Advantages of GRP

Low weight

CTS GRP products make manufacturing structures easier than ever before. Their incredibly low weight makes them easy to process, which simplifies the entire production process. But that's not all: these products also enable enormous weight savings in the final structures, which brings advantages not only in economic terms but also in ecological terms. In addition, the low weight of GRP products can drastically reduce transport and processing costs, making them a particularly cost-effective solution. With CTS's offerings, customers can therefore benefit not only from ease of handling, but also from significant cost savings compared to other options.

- Reduce transport costs

- Easy to process

- Lighter end constructions

High strength like steel

CTS has set the bar high with its latest developments: GRP products that are as strong as steel! This futuristic material offers an incredible combination of strength and low weight. It withstands both tensile and compressive forces extremely well. CTS's GRP products have the same strength as steel, but are only a quarter of the weight. This promises numerous applications in various industries. These truly amazing properties have made CTS a series producer in the industry, especially in railway infrastructure. #StrongAsSteel

- Same strength as steel

- Absolutely break-proof

- Dimensionally stable

Durability

GRP products are always used when durability and longevity are required. The reason for this is that GRP consists of a composite of resin and glass fibers, creating a unique combination of the properties of these materials. GRP products are not only weather and chemical resistant, but also resistant to corrosion and UV radiation. These properties make GRP the ideal solution for use in harsh environments and under extreme conditions. It easily stands the test of time – with a service life of over 50 years. GRP products are therefore a sustainable and secure investment for your company.

- No corrosion

- Weather-resistant

- Resistant to chemicals and UV radiation

Electrically insulating

One of the advantages of fiberglass reinforced plastic is that it allows for a high degree of flexibility in use. It is non-magnetic and electrically insulating, making it particularly suitable for areas where high voltages occur. Glass fiber reinforced plastic is a modern and reliable material that is increasingly found in industry and other sectors.

- Electrically insulating

- Non-magnetic

- No grounding necessary

Easy processing

Fiberglass is a great alternative to wood when it comes to easy and precise cutting. The material can be cut to size with a jigsaw without producing splinters or dust. This makes it ideal for applications where quick and easy cuts need to be made on site. Even complex shapes can be easily worked with this material. In addition, fiberglass can be customized and painted. Overall, it is an extremely versatile and user-friendly material that can be used in many areas.

- Can be worked like wood

- Can be worked like wood

- No maintenance

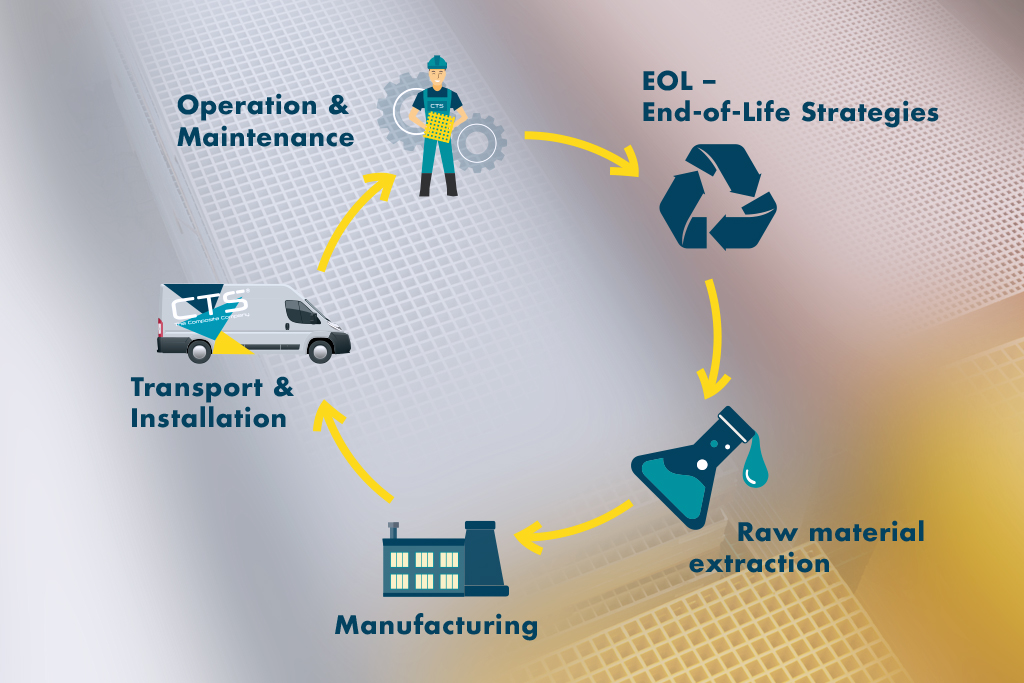

Sustainability

GRP products are a sustainable alternative to steel: their density is up to 75% lower, which significantly reduces CO₂ emissions during transport.

Excess GRP is recycled using a patented process, allowing up to 70% of the material to be reused as a raw material or energy source.

A unique take-back system ensures 100% recycling. GRP, consisting of glass fibers in a thermoset matrix, is used in the cement industry as a substitute for primary raw materials and fossil fuels.

Recycling 1,000 tons of GRP saves around 450 tons of coal, 200 tons of lime/chalk, 200 tons of sand, and 150 tons of aluminum oxide—without leaving any residues such as dust or ash.

- Low CO2 emissions

- Up to 100% recycling

- Up to 100% recycling

Minimal maintenance

Fiberglass is an extremely durable material with many advantages. It offers high mechanical strength and is resistant to chemicals, corrosion, and UV radiation. In addition, it is environmentally friendly and has high temperature stability. Thanks to all these properties, GRP has a long service life and requires no maintenance. If you are looking for a material that is extremely resilient yet lightweight and durable, fiberglass reinforced plastic is definitely an option you should consider.

- Service life of over 50 years

- Weather-resistant

- Resistant to chemicals and UV radiation

Applications of GRP

GRP impresses with its excellent properties and extreme resilience in many industries such as railway construction, plant engineering, hydraulic engineering, and architecture.

GRP in railway infrastructure

Safe, low-maintenance, and efficient—GRP constructions in track construction.

GRP in plant engineering

Corrosion-resistant for a maintenance-free future.

GRP in hydraulic engineering

GRP jetty systems have proven themselves as a durable solution.

GRP in architecture

One material, endless possibilities.

How is GRP manufactured?

CTS uses state-of-the-art production processes to optimize the properties of GRP:

Pultrusion process

Pultrusion technology enables the fast and precise manufacture of GRP profiles. Glass fibers are impregnated with resin, shaped, and cured. With over 1,000 profile dimensions, CTS offers one of the largest product ranges in accordance with EN 13706 E23.

Wet lamination process

GRP gratings are produced by impregnating glass fibers with resin in a mold. Curing takes place under pressure and heat. Production complies with DIN standards 24537-1 to 3.

Hand lamination process

For small and medium series, glass fiber mats are impregnated with resin and cured by hand. Ideal for prototypes and one-off productions.